Japanese traditional crafts

Ceramic art

Japanese ceramics are highly-evaluated internationally along with China and Korea.

Since ancient times Japanese had made earthen vessels.

In the 5th century, the technology of making on a wheel and being burnt in a kiln was introduced from Korea.

In the 8th century, glazed potteries are imported from China and such potteries were begun to make in Japan.

Around this period, several production areas were born mainly in western Japan.

In the 16th century, Korean potters introduced the method of beautiful porcelain, and many products were exported to Europe.

After this, Japanese potters have continued to improved making technology.

Famous production areas of ceramics

"Yaki" in the following names means "burning in a kiln".

- Seto-yaki : Aichi prefecture.

One of the most oldest production areas.

The porcelains for daily use are mass-produced. - Tokoname-yaki : Aichi prefecture.

One of the most oldest production areas.

Red clay is used, so reddish teapot or cup are famous.

Seto-yaki, Photo by Seto city

Tokoname-yaki

- Mino-yaki : Gifu prefecture.

In this area, half of all Japanese potteries are produced.

The deformative potteries which Oribe Furuta started to make in the 16th century is famous as artwork. - Shigaraki-yaki : Shiga prefecture.

One of the most oldest production areas.

Various potteries for daily use are produced.

Pottery figurine of Japanese raccoon is famous.

Oribe ware (A kind of Mino-yaki)

Racoon figurines of Shigaraki-yaki

- Kutani-yaki : Ishikawa prefecture.

It started since the 17th century.

Colorful and graceful painting covers the pottery all over. - Kiyomizu-yaki : Kyoto prefecture.

It has been produced aroudn Kiyomizu-dera temple in Kyoto city started since the early 17th century.

Kyoto was the capital of Japan and the potters had come from the all over Japan, so various techniques are used for this pottery.

Kutani-yaki

© Ishikawa Prefectural Tourism League

Kiyomizu-yaki

- Bizen-yaki : Okayama prefecture.

One of the most oldest production areas.

The pottery is made without glaze, and is simple and practical. - Hagi-yaki : Yamaguchi prefecture.

It is said that it started by the the traditional technology from Korea at the 17th century.

The looking is quiet, but becomes deep flavor during using.

Bizen-yaki

Hagi-yaki

- Karatsu-yaki : Saga prefecture.

It started in the 15th century, and many nice potteries for tea ceremony were produces.

This keeps the traditional technology from Korea. - Arita-yaki (Imari-yaki) : Saga prefecture.

In the 17th century, many Korean potters are invited, and one of them started to make nice porcelain here.

Many "Imari-yaki" were exported to Europe in that century.

It is very beautiful porcelain.

Karatsu-yaki

Photo by Karatsu Tourism Association

Arita-yaki

- Mashiko-yaki : Tochigi prefecture.

It is one of the few pottery in the eastern Japan and started in the late 19th century.

Potter's clay includes much sand, so the pottery is thick and simple. - Tsuboya-yaki : Naha city in Okinawa prefecture.

It is a pottery produced since around the 16th century in the period of Ryukyu Kingdom, and it is called "Yachimun" in Okinawa dialect.

The cray contains iron, and the pottery has massive feeling but is simple.

The pattern on the pottery is powerful and is influenced by China and the other Asian countries.

Mashiko-yaki

Tsuboya-yaki

Lacquerware

Lacquerware is the craftwork which is coated with natural resin extracted from sap of "urushi" (Japanese lacquer tree).

Mainly wooden box, bowl, chopstics, etc. are coated with Japanese lacquer.

The products has tasteful color and luster.

Lacquerware is made by alternating between coating and polishing again and again.

After that some products are added the following decorations.

Urushi tree

Makie

- Makie : Some picture are painted with lacquer.

While it is wet, gold or silver powder are sprinkled on it and it is polished. - Chinkin : Some patterns are engraved on the lacquer with knife, and gold or silver foil are put into there.

- Raden : The inside of shell shining in rainbow color is shaved thinly as many chips, and they are enchased on the lacquer.

Chinkin

Raden

Famous production areas of lacquerware

- Aizu-lacquerware : Western area in Fukushima prefecture.

Since the 16th century it is produced.

Various techniques are used. - Wajima-lacquerware : Noto peninsula in Ishikawa prefecture, and most famous production area in Japan.

Diatomite produced in this area is mixed in lacquer, so the product is tough.

Aizu-lacquerware

Photo by Fukushima Prefecture

Wajima-lacquerware

© Ishikawa Prefectural Tourism League

- Yamanaka-lacquerware : Ishikawa prefecture.

Originally this was produced as souvenir for tourists of hot spring resort.

But since the 20th century this changed to mass-produce.

Now, amount of production is top in Japan. - Kiso-lacquerware : Nagano prefecture.

Since old times, forestry has been a main industry in Kiso area.

So lacquerware has been producing since the 18th century.

Yamanaka-lacquerware

© Ishikawa Prefectural Tourism League

- Kishu-lacquerware : Wakayama prefecture.

This is one of famous production areas, so not only traditional products but also advanced ones are made. - Ryukyu-lacquerware : Okinawa prefecture.

When this area was the Kingdom of Ryukyu in the 14th, this started to produce for tribute to China.

It has bright color.

Kishu-lacquerware

Photo by Wakayama Tourism Federation

Ryukyu-lacquerware

© Okinawa Convention & Visitors Bureau

Traditional textiles

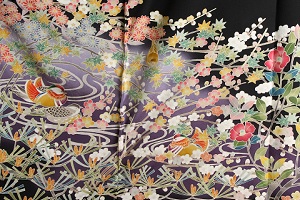

Japanese traditional textiles are mostly for Kimono.

Of course, there are various types from gorgeous to casual.

Luxury Kimono is a product of silk.

Especially, Nishijin weaving and Yuzen dyeing have been the two important traditional technics to produce such Kimono.

Nishijin weaving

Nishijin weaving is a technic to make a luxury cloth by weaving.

First, the design of cloth for kimono is drawn on a paper and is copied to graph paper and colors are decided.

To weave the cloth, all threads are produced and dyed to the the necessary colors.

According to the data of above graph paper, the cloth is woven with the threads.

The workshops are in Nishijin area to the west of Kyoto Imperial Palace.

Yuzen dyeing

Yuzen dyeing is a technic to make a luxury cloth by dying.

"U" in the word is pronounced long, so it is read as "yûzen".

The name of Yuzen came from Miyazaki Yuzen (1654-1736) who was a painter.

His painting style has been used for this cloth.

First, the design for kimono is drawn on the cloth directly by dyes.

After that, some processes of dying are performed.

Finally, the cloth is washed in flowing water.

It was once performed in the river, but it has been performed in the artificial river in the factory for good water quality.

Kyo-yuzen made in Kyoto city and Kaga-yuzen made in Kanazawa city are famous.

Drawing work of Kaga-yuzen

Photo by Kanazawa City

Washing work of Kaga-yuzen

Photo by Kanazawa City

Kaga-yuzen, Photo by Kanazawa City

Experience of wearing kimono of Kaga-yuzen

Photo by Kanazawa City

Other popular Traditional textiles

- Chirimen : It is also a textile woven with silken, and the method of weaving is the same as "crepe".

The fine rugged surface strengthens the elegancy, so Chirimen is good material for Kimono.

Tango-chirimen produced in Tango area to the north of Kyoto is famous. - Tsumugi : It is a textile woven with cotton yarn or low-quality silken threads.

It has been used for casual wear or work clothes.

Yuki-tsumugi made in Ibaraki and Tochigi prefecture, Oshima-tsumugi made in Amami-Oshima Island in Kagoshima prefecture are famous. - Bingata : It is a dyeing in Okinawa area, and it has colorful patterns.

It started to produce in the 14th century in the period of Ryukyu Kingdom.

This is used for not only Okinawan dress but also wall hanging, store curtain, etc.

Oshima Tsumugi silk

Photo by Kagoshima Prefecture Visitors Bureau

Okinawan kimono by bingata

Washi (Traditional Japanese paper)

Traditional Japanese paper is called Washi in Japanese.

Papers which we usually use now are produced from pulp.

But washi are made using fibers from the bark of "gampi" tree, "mitsumata" shrub, or "kouzo" (paper mulberry) tree.

Washi is stronger and more durable than general paper.

So it is used as not only sheet for calligraphy or Japanese painting but screen of sliding door in Japanese room.

Additionally, Japanese banknotes contain washi.

Mitsumata, one of materials of washi

Making washi

Washi is produced in various regions in Japan, but the amount of production is far lower than general paper.

Because the production of washi needs many hands, so is unsuitable for mass production.

The trees as raw materials are grown in the fields, therefore forests are protected from destruction.

Through the production process, little chemicals are used and little fuels are needed.

So they say washi is eco-friendly.

Washi on Shoji (paper screen)

Chiyogami of Washi

Japanese sword

Japanese sword has been produced since ancient times.

Of course, it is well known that samurai holds it and uses it for battle.

Japanese sword was certainly a symbol of samurai.

Moreover, Japanese sword had been a symbols of high rank and power, a guardian of the person, and a special artwork.

Japanese sword curves slightly and haves a single edge.

And the temper pattern of a sword blade is beautiful.

Japanese sword had been produced in main five areas:

Nara, Kyoto, Bizen (in Okayama Pref.), Kamakura (in Kanagawa Pref.), Mino (in Gifu Pref.).

After the end of samurai era in 1868, Japanese sword has been handled as a traditional artwork.

Many historical Japanese swords are designated as national treasures and national important cultural properties, and are displayed in major museums.

Now, we can see the works of traditional swordsmith in Osafune in Bizen area and Seki in Mino area.

Japanese sword

Shaft and handguard of Japanese sword

Ornament for display

Various ornaments have been producted traditionally in Japan.

They are displayed in the living room, Buddhist altar, business place, etc.

It is believed that the ornament attracts happiness, fortune, prosperity, etc.

- Japanese Doll : It is the doll having Kimono and Japanese hairstyles.

Most of them are standing figures and some of them hold a dancing pose.

Mainly, body, hair and Kinono are produced by each specialist.

The dolls are mainly produced in Tokyo and Kyoto. - Hakata Doll : It is a kind of Japanese doll, and it has been produced in Hakata area in Fukuoka city in Kyushu.

It is made by baking the cray and painting on the body.

The facial expressions are charming and beautiful. - Hina Dolls : They are the dolls for the Doll's Festival (March 3) to hope the happiness of girls.

The families having girls decorate a set of the dolls in the house once a year.

A couple of sitting dolls like emperor and empress are main, and some other servants and various goods are decorated.

Saitama Prefecture near Tokyo accounts for half of the total production amount in Japan.

Japanese doll, Hakata doll

Hina Dolls

- Samurai warrior dolls : May 5 is Children's day in Japan, and it is also the day to hope the happiness of boys.

The families having boys decorate a set of the dolls in the house once a year.

A doll of fighting samurai warrior, strong god, noble boy or Japanese armor is decorated. - Kokeshi : It is the simple wooden doll and is the folk craft which has been produced mainly in Tohoku region since the early 19th century.

It consists of a round head and a cylindrical torso.

The head is fitted on the torso and a girl's face is drawn in it.

Samurai warrior dolls

Kokeshi

- Daruma : It is the hollow and round self-righting doll, and it has been produced since the 17th century.

Daruma was a Chinese Zen priest around the 5th century, and it is said that he continued to sit in Zen meditation for nine years, so the doll is modelled after his Zen meditation.

It has been produced as a popular lucky charm in various areas since ancient times. - Maneki-neko : It is the doll of cat translated as "beckoning cat" in English, and it has been produced since Edo Period.

It generally has either its right paw or its left paw raised.

It is said that right paw brings money and left paw brings guests.

So, it is a lucky charm for prosperity in business.

Various types of Maneki-neko are sold, but major ceramic Maneki-neko is produced in Tokoname and Seto cities in Aichi Prefectutre.

Daruma

Maneki-neko

Traditional daily necessities

In the long history, Japanese people have created various daily necessities.

The products reflect Japanese nature, culture and sensibility.

But, some products are going out by alternative industrial products and shortage of successors.

- Nanbu iron kettle : It is the iron kettle produced in Morioka and Oshu cities in Iwate Prefecture.

First, iron teakettles for tea ceremony was produced in this area in the 17th century, and various iron kettles became the local specialty.

The kettle retains heat and the boiled water becomes tasty. - Kitchen knife : Japanese kitchen knives are used for Japanese cooking.

They are required to cut foods easily, beautifully and delicately.

The products are received attention from foreign chefs.

Three major producing areas are Sakai city (near Osaka), Seki city (Gifu Pref.) and Sanjo city (Niigata Pref.).

Nanbu iron kettle

Japanese Kitchen knives

- Kiriko : It means Japanese cut glass.

In the late 19th century, Edo (current Tokyo) and Satsuma (current Kagoshima in Kyushu) started the production. - Magewappa : It is a lunch box made of steam bending wood.

It is portable and the flavor of cooked rice and foods in the box is kept for long time.

It has produced in many mountain areas, and Magewappa produced in Odate city in Akita Prefecture is popular.

Edo Kiriko

Magewappa filled with lunch

- Sensu : It is Japanese folding fan.

A sector-shaped paper is attached on many frames of bamboo or wood, and it is foldable.

It is a fan for cooling by waving it on a hot day.

Rather, it is an accessory of ceremonial dress and an item of Japanese dance.

Kyoto is the largest producer, and it is also produced in Nagoya and Kyoto. - Uchiwa : It is Japanese unfolding fan.

A round paper is attached on the frames of bamboo or wood.

It is also a fan for cooling by waving it on a hot day, and it has been used in the daily life of common people.

Cheap Uchiwa are found in various places, but there are Uchiwa products as traditional craft.

Sensu

Traditional Boshu-Uchiwa

- Japanese umbrella : It is produced by covering with Washi (Japanese paper) on many bamboo ribs.

The paper is saturated with oil, so the umbrella is tough.

It is possible that various colors and patterns are used on the paper.

Now western-style umbrella is used daily in Japan, so Japanese umbrella is mainly used in ceremony and festival.

Gifu city in Gifu Prefecture is the largest producer. - Chochin : It is Japanese lantern.

The body is made of Japanese paper attached on many thin bamboo frames and it is foldable.

It is used in various ceremony, event, and a sign of a shop.

It is also an offering to the gods and Buddha.

The huge red chochin of Sensoji temple in Asakusa in Tokyo is well-known.

Japanese umbrellas

Chochin

- Furoshiki : It is the square cloth to wrap goods.

It had been used as daily necessaries until the late 20th century, but it has been declining because of the spread of plastic bags.

Now, it is recognized once again from the viewpoint of environmental conservation. - Fûrin : It is small, bowl-shaped Japanese wind chime.

It is hung in summer and it rings sweetly with just a slight breeze.

By the sound, people feel a coolness.

The body is made of metal or glass, so the sound differs depending on the material.

A present wrapped with Furoshiki

Fûrin